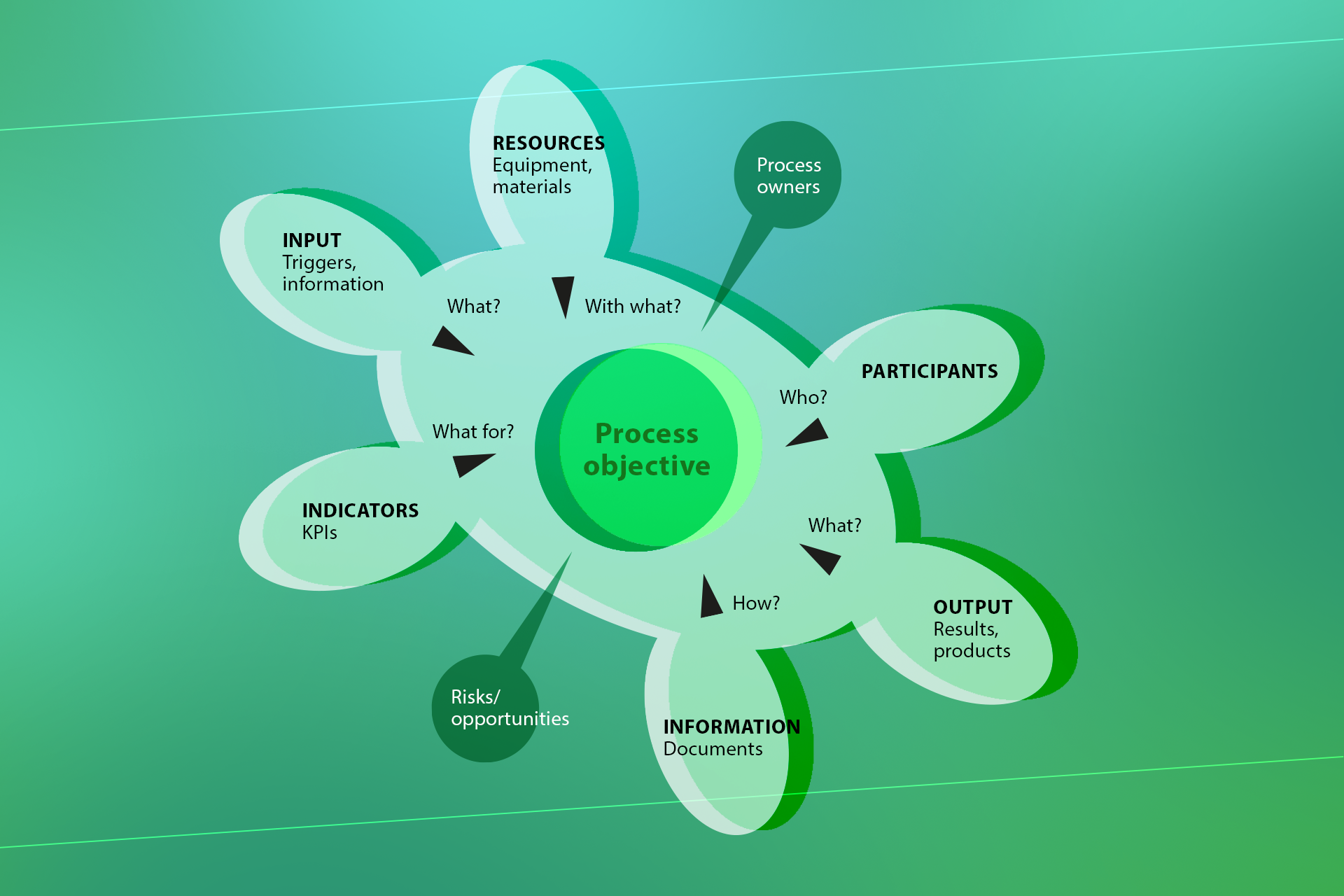

Clause 4.4. of the standard, “Quality Management System and its Processes”, requires you to determine and define the management, core and support processes and corresponding process parameters for the QMS. These parameters include the following points, which you will recognize from the Turtle Diagram:

Required inputs and expected results of processes

Process sequences and interdependencies

Criteria and procedures for effectively implementing and controlling processes

Resources and their availability

Responsibilities and authorities

Risks and opportunities

It is vital to determine, apply, assess and improve these process parameters. This makes it possible to evaluate processes, implement changes, and achieve process optimizations.

Process orientation plays a similar role in the ISO/TS 16949 quality management standard, which applies to the European and North American automotive industry. Both standards require companies to implement process orientation but do not explicitly refer to Turtle Diagrams. Instead, companies are free to determine how they conduct process analysis in compliance with the standard and demonstrate this in audits. The Turtle Method is simply a particularly suitable tool that has become established in practice.